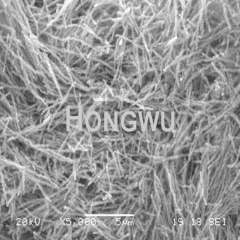

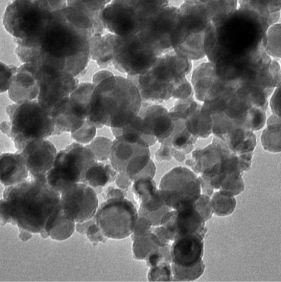

Silicon Carbide (SiC) Nanopowder / Nanoparticles (SiC, beta, 99%, 50nm, cubic)

Silicon Carbide (SiC) Nanopowder / Nanoparticles (SiC, beta, 99%, 50nm, cubic)

Technical parameters of Silicon Carbide (SiC) Nanopowder / Nanoparticles:

Particle

size: 50nm, 100nm, 500nm, 100-200nm, 0.5um, 1-2um, 5um, 7um, 10um, 15um

Purity: 99%

Note:

Other size specifications of the products, we can provides customized

production.

Decomposition Temperature: 2973k

Thermal Expansion Coefficient: 6.58x10-6 at 373k

Thermal Expansion Coefficient: 2.98x10-6 at 1173k

Compressibility Coefficient: 0.21x10-6

Density (288k): 3.216 g/cm3

Hardness: 9.5 Mohs

Heating Power (KJ/mol): 30.343

Characteristics of Silicon Carbide (SiC) Nanopowder / Nanoparticles:

1.

Beta SiC powder has high chemical stability, low thermal expansion coefficient,

high thermal conductivity, resistance temperature characteristics is opposite

to metal;

2

Beta SiC powder has high hardness, with

Mohs hardness of 9.5, next to the dismond, is the wear-resisting material;

3.

Beta SiC powder has high temperature resistance, corrosion resistance,

resistance to acid and alkali solvent

4.

Beta SiC powder has good toughness, superior grinding performance, excellent

thermal conductivity of electricity.

Application fields of Silicon Carbide (SiC) Nanopowder / Nanoparticles:

As

modified high strength nylon material: nano Beta SiC powder has good

compatibility dispersion in polymer composites, and good basic associativity,

after modified the strength of nylon alloy tensile is 150% higher than ordinary

PA6, wear-resisting performance increased more than three times. Mainly used

for the armored tracked vehicle polymer parts, automotive steering parts,

textile machinery, mining machinery lining board.

As modified special engineering plastics

polyether ether ketone (PEEK) wear-resisting performance: when adding quantity

is approximately 5%, can greatly improve and raise the wearability of PEEK

(increased by more than 30%)

More information, pls contact us at hwnano@xuzhounano.com.

by Alisa

日本語

日本語 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917